This isn't my first batch but my first batch was maybe 14 blossoms? And they gave such incredible color that I kept going back for more, because as soon as I deadhead, the blooms come right back.

I think this was the first batch. I've since learned that the dye is very soluble so that it requires very little cooking, a big plus in hot weather.

That is not the first batch but you can see the bath already pretty potent.

This was my second round of dyeing, and I can tell because I had done the first dyebath as a shoving a ball of hanji into the dye because I didn't have a big place to spread out flat and brush on. Then I took it to the studio to start to mordant with alum. It brought the color out dramatically.

So every day I just do one round (one or two days I managed two but I don't push myself to do that): either a dye round, or a mordant round. Most batches (and these are batches of TWO sheets at a time, since I don't have enough flat space and didn't feel like laying plastic out on the floor) were dye/mordant/dye but one batch I went dye/mordant/dye/mordant/dye.

This was a scrap of a different type of hanji (different mill, different location in Korea, different papermaker), and I have no idea why the dye took in this weird uneven blush-y way, but you can see the mordant is going down starting at the right side.

This was an extra productive day because I dyed and also made bark lace.

And then started to cord some of the dyed paper, but not all of it.

I cooked for a friend on July 4 and didn't want to do my work so instead I sewed these pants out of a gift from a friend years and years ago when she used to live in the Philippines (though an anthropologist recently said it was Indonesian. I have no idea and I hope it wasn't bad spiritually for me to cut up a wrap to make pants).

One day a box arrived on the front stoop that I was not expecting. But once I opened it, surprise! The "encyclopedia of inspiration" published by Uppercase has been printed and my copies arrived.

It's generous to us all, giving a bunch of splashy spreads, and it seems they got a competent writer to make sense of all of our writing that was requested last fall!

Back in the studio, I experimented by dragging in my papermaking equipment to the beater room so that I could feel a little more at ease with a readily accessible drain. I didn't really need it but I also did design the room to be big enough to make paper if I wanted to inside of it. Something about the room makes me feel safe, more contained.

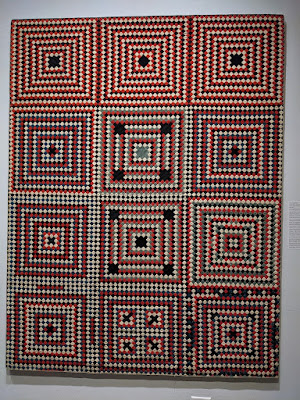

I beat up a bunch of Rives BFK scraps with a touch of premium abaca. Weirdly, the beater did not leak where I expected it to, but it did start to spurt out the back end again, so I was so glad I still have my beater lid handy. After adding sizing and then retention aid to the load in the beater with plenty of time to brush it, I took it out into three buckets and threw in burnt umber pigment I got from windmills near Amsterdam.

I used Velma's recipe for dry pigments and it worked! Then I tried to take it easy and only made a third of the batch each day instead of attempting to beat and pull the whole load in one day.

These are the sorted sheets in progress, before I'm done with the batch. You can see I am still having issues with my mini-split (remote is off the wall to remind me to tweak, manuals are on the chair). The HVAC "professionals" who installed the units I think didn't do them right because they leak. I think this is a pretty easy thing to do right and yet easier to do wrong, and here I am with lots of water dripping into a vat weighed with an old gym weight on the windowsill.

Abby from Oberlin came out to record sounds in my studio after I recorded an interview with her on campus two days prior. I had soaked these hanji scraps to run in the beater and guess what? It shorted again or whatever, where it wouldn't turn on. So clearly I need to do something with the switch/motor connection or replace both. I can't deal with any of it now. When I ran this load, it started to leak again in the likely spots and I still have to sort out a way to catch the leaks safely. Also, I finally discovered the original source of the rust bits: the bedplate! Which I DID not epoxy/seal, which was so dumb because I had so much time to do that if I had not been so ignorant. At least I know, but I don't feel like taking the underside apart again to take it out. For now....all I can say is that I do not make archival paper out of this beater!!

But the marigolds that have been in my freezer for up to 9 years have been giving me lots of cheer! I am so impressed. They work well. All I'd say is, the blossoms lose their moisture, so you want to cook with probably twice the water you would with fresh ones, it just gets sucked up into the flowers.

Next week is another annual hanji retreat! The biggest class yet, and the most mixed group, so it will be another big adventure. I also have tons of work I've been avoiding and to do that, I spent hours yesterday making samosas from scratch (the dough as well). Time to fry them up and deliver them as a belated birthday gift!

Rag & Pulp encyclopedia

Velma's recipe for dry pigment in papermaking is in the Paper and Colour book.